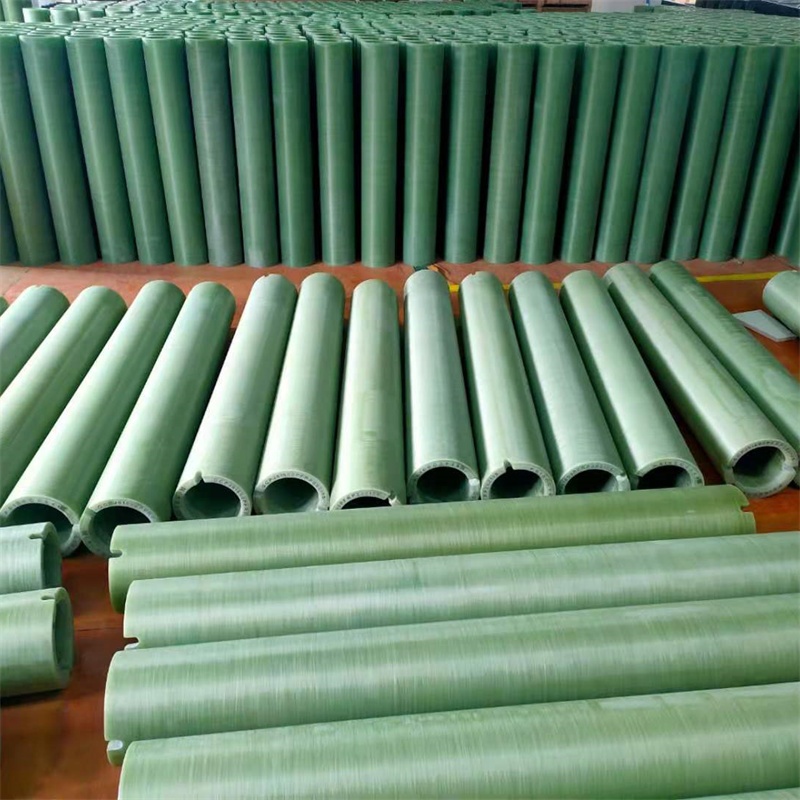

Knowledge Science | Explore FRP Pipes (FRP Tube)

In recent years, with the rapid development of the economy, the construction industry segment - the pipeline industry has also developed rapidly, with a large number of enterprises and rich product types. The performance of FRP pipes and hot-dip plastic steel pipes (plastic-coated steel pipes) in the field of cable protection pipes Especially eye-catching. Today, I mainly introduce FRP pipes. For those who do not know much about the pipeline industry, FRP pipes may be unfamiliar.

What is FRP pipe?

FRP (Fiberglass Reinforced Plastic) is fiberglass reinforced plastic, which is a composite material consisting of a fiber-reinforced polymer matrix. Therefore, FRP pipe is a pipe made of FRP material by contact forming or winding method. Various types of resins are used to obtain specific FRP pipe properties in the final product, such as thermoset polyesters, epoxy resins, phenolic resins, etc. The most widely used reinforcement material is fiberglass "E-glass". As a corrosion-resistant alternative to metal piping, FRP piping systems are used worldwide. By choosing FRP as the pipe material, the need for inner linings, outer coatings and cathodic protection can be easily eliminated. FRP piping systems are available in a variety of sizes , from 1 inch to 144 inches.

Main raw material of FRP pipe : (33%) alkali-free chopped strand mat (glass fiber) + (63-65%) transparent unsaturated polyester resin composition, in addition to: surface weather-resistant film + curing agent + accelerator + flame retardant + pigment + other additives. If there are more glass fibers and less resin, there will be fiber leakage (there is a phenomenon of leakage on the surface or side); if there are less fibers and more resin, there will be a sound when folded.

The performance of FRP pipes

Main features that make FRP Pipes ideal for various industries worldwide are :

Corrosion preventive

FRP pipes have inherited corrosion resistance. In most cases, fiberglass reinforced plastics are the only materials that can handle certain service environments. Furthermore, their corrosion resistance is often combined with their cost advantage, making them the most acceptable solution. The corrosion resistance of fiberglass reinforced plastic piping is a function of the total resin content and the resin used in the piping laminate. Therefore, higher resin content means higher corrosion resistance.

Weight advantage

FRP pipes have a low weight-to-strength ratio, which is another significant advantage of FRP pipes. For the same strength, fiberglass-reinforced plastic pipes are about half the weight of aluminum and one-seventh the weight of stainless steel. Lightweight properties are critical, especially when considering the ease and cost of ductwork installation. The inherent light weight of FRP piping is a major advantage when equipment must be installed on existing structures such as roof or mezzanine scrubbers. The high strength of FRP pipes plays an important role in the design of various FRP equipment and applications such as pultrusion profiles. In addition, the combination of high strength and lightweight properties makes FRP pipe suitable for filament wound pipes and pipes.

Economy

Lower cost is a major advantage of using FRP pipes, as they provide an effective corrosion solution at the lowest cost compared to materials such as titanium, rubber linings, and stainless steel. However, the cost advantages of such materials depend primarily on design considerations, application, pressures involved, availability, raw material cost and product configuration.

Flexibility

FRP pipes are versatile in their applications, but often overlooked. However, it's important to note that you can do some things with fiberglass reinforced plastic tubing that other off-the-shelf materials can't do efficiently and economically. FRP pipe can be used in any equipment or configuration that can build permanent or temporary molds. For example, piping work with FRP pipe is very easy because you can make all types of tee inlets, rectangular transitions, circular transitions, elbows and flanges at minimal cost. Fiberglass reinforced plastic pipes can also be used to line new and existing structures. Through the use of computer software programs, the design of FRP systems has been greatly improved. These programs mainly include : chemical composition, gas flow analysis, liquid flow analysis, thrust block analysis, free span analysis and installation information. This is important to ensure that the specific requirements of different industries are fully met in order to guarantee maximum efficiency of the FRP pipeline.

It also has disadvantages :

fluids with temperatures over 100 degrees Celsius .

Slight UV degradation was found to occur, which can be reduced by using pigments, dyes, UV stabilizers, fillers, etc. in the resin system.

FRP pipeline application field

Due to its high durability, corrosion resistance and moderate strength, the use of FRP pipes is increasing day by day. FRP piping systems are used in various industries such as:

Drinking water and desalination industry

Chemical, petrochemical, oil and gas industries

Ducts and Ventilation Ducts

Irrigation and Sanitation Services

Water distribution and delivery

Mud pipeline

Power plant, etc.