Applications of Fiberglass Reinforced Plastic (FRP) Pipes in Petrochemical Industry

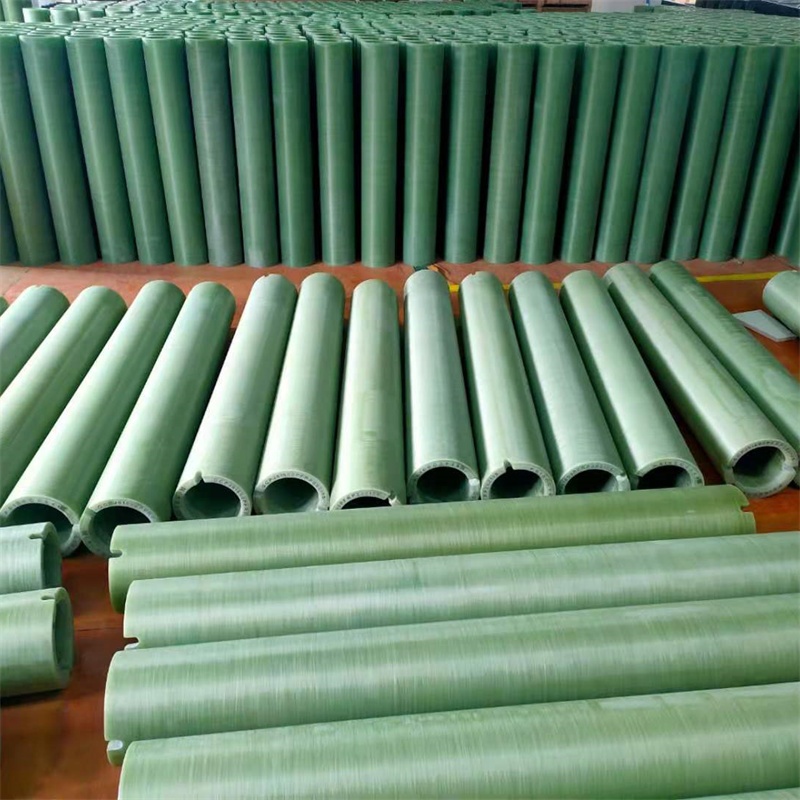

Introduction to Fiberglass Pipes

Fiberglass pipes, also called GRP (Glass Reinforced Plastic) pipes, are composite materials made of glass fibers and a polymer resin matrix. They have various applications across different industries, including the petrochemical industry, where they are widely used for their corrosion-resistant properties and cost-effectiveness. This article discusses the manufacturing process, advantages, applications, and market prospects of fiberglass pipes in the petrochemical industry.

Manufacturing Process of Fiberglass Pipes

The manufacturing process of fiberglass pipes involves multiple steps, including filament winding, lamination, and curing. First, glass fibers are impregnated with a resin matrix and wound around a mandrel in a specific pattern to form a continuous filament winding. Then, multiple layers of glass and resin are laminated onto the wound layer until the required thickness is achieved. Finally, the pipe is cured through a heat treatment process to produce a rigid composite structure.

Characteristics of Fiberglass Pipes

Fiberglass pipes have several properties that make them attractive in the petrochemical industry. These include:

? Corrosion-resistant: Fiberglass pipes are highly resistant to chemical corrosion, making them suitable for transporting aggressive fluids in harsh environments.

? Lightweight: Fiberglass pipes offer significant weight savings compared to traditional metallic piping systems, making them easy to handle and transport during installation and maintenance.

? High-temperature performance: Fiberglass pipes can withstand high operating temperatures, making them ideal for high-temperature applications such as steam lines.

? Durable: Fiberglass pipes have a long service life and require less maintenance compared to traditional metallic piping systems.

Applications of Fiberglass Pipes in the Petrochemical Industry

Fiberglass pipes have various applications in the petrochemical industry, including:

? Tank farm piping systems: Fiberglass pipes are used to transport chemicals and petrochemicals in tank farms.

? Pipeline systems: Fiberglass pipes are used to transport crude oil, natural gas, and other fluids across long distances in pipelines.

? Filtration systems: Fiberglass pipes are used in filtration systems to separate solids from liquids or gases.

? Emergency safety systems: Fiberglass pipes are used in emergency safety systems such as fire sprinkler systems, where they need to withstand the high pressure caused by fire suppression systems.

? Other applications: Fiberglass pipes are used in other applications such as cooling water systems, acid gas removal systems, and desalination plants.

Table of Common Specifications for Fiberglass Reinforced Plastic (FRP) Pipes in Industrial Applications.

| Model | Diameter (mm) | Thickness (mm) | Length (m) | Working Pressure (MPa) | Temperature Range (℃) | Corrosion Resistance | Application |

|---|---|---|---|---|---|---|---|

| GRP001 | 25 | 3.0 | 6.0 | 1.0 | -40~120 | Acid, Alkali | Petrochemical, Environmental Protection |

| GRP002 | 50 | 5.0 | 12.0 | 1.6 | -20~100 | Salt, Hydrofluoric Acid | Environmental Protection, Electric Power |

| GRP003 | 80 | 8.0 | 6.0 | 2.5 | -10~80 | Acid, Alkali, Salt | Petrochemical, Environmental Protection |

| GRP004 | 100 | 10.0 | 12.0 | 3.0 | -30~150 | Acid, Salt, Oxygen | Environmental Protection, Electric Power |

| GRP005 | 150 | 15.0 | 6.0 | 4.0 | -20~120 | Hydrofluoric Acid, Acid | Petrochemical, Environmental Protection |

| GRP006 | 200 | 20.0 | 12.0 | 5.0 | -25~130 | Alkali, Salt | Environmental Protection, Electric Power |

Advantages of Fiberglass Pipes in the Petrochemical Industry

The following are some advantages of using fiberglass pipes in the petrochemical industry:

? Lower lifecycle costs: Fiberglass pipes have a lower lifecycle cost compared to traditional metallic piping systems due to their longer service life and lower maintenance requirements.

? Improved safety: Fiberglass pipes reduce the risk of leaks and spills, which can have catastrophic consequences in the petrochemical industry. They also have better fire resistance properties, reducing the risk of fires.

? Easy to install and maintain: Fiberglass pipes are lightweight, making them easy to install, handle, and transport. They also require less maintenance compared to traditional metallic piping systems, reducing downtime.

? High corrosion resistance: Fiberglass pipes are highly resistant to corrosion from chemicals, making them suitable for transporting aggressive fluids.

Fiberglass Pipe Fittings and Installation Methods

Fiberglass pipe fittings include couplings, elbows, reducers, flanges, and valves. These fittings are designed to connect and control the flow of fluids in a piping system. The installation of fiberglass pipes involves the use of special tools and techniques such as cutting, sanding, bonding, and sealing. The fittings are also designed to be compatible with the pipe's diameter and pressure rating.

Maintenance and Inspection of Fiberglass Pipes

Regular maintenance and inspection of fiberglass pipe systems are essential to ensure their proper functioning and prolong their service life. This involves cleaning the pipes to remove any build-up or sediment, checking for any signs of damage or wear, and replacing or repairing any damaged sections.

Market Prospects of Fiberglass Pipes in the Petrochemical Industry

The global fiberglass pipes market is expected to grow at a significant rate due to the increasing demand for fiberglass pipes in various applications, including the petrochemical industry. The high demand for lightweight, corrosion-resistant, and cost-effective piping systems is driving the growth of the fiberglass pipes market. Additionally, the increasing adoption of fiberglass pipes in the oil and gas industry is expected to create new opportunities for the market.

Case Studies of Fiberglass Pipe Applications in the Petrochemical Industry

Case Study 1: Fiberglass Pipes in Chemical Production

A chemical production plant in Canada was facing frequent leaks and corrosion in their traditional metal piping systems. They decided to switch to fiberglass pipes, which offered better corrosion resistance and durability properties. The fiberglass pipes withstood the harsh chemical environment and reduced maintenance costs, resulting in significant cost savings for the plant.

Case Study 2: Fiberglass Pipes in Oil Transportation

A pipeline company in the Middle East decided to install fiberglass pipes to transport crude oil over long distances. The fiberglass pipes offered improved resistance to corrosion, reduced the risk of leaks, and provided better insulation properties, reducing heat loss during transport. The installation of fiberglass pipes resulted in improved safety, cost savings, and a longer service life compared to traditional metallic piping systems.

Case Study 3: Fiberglass Pipes in Environmental Protection

A desalination plant in China replaced their corroded metallic piping systems with fiberglass pipes to meet environmental regulations. The fiberglass pipes offered better durability, corrosion resistance, and reduced maintenance requirements, resulting in cost savings for the plant. Additionally, the pipes' lightweight properties made them easier to handle during installation.

Conclusion

Fiberglass pipes have numerous advantages over traditional metallic piping systems, making them increasingly popular in the petrochemical industry. The high demand for lightweight, corrosion-resistant, and cost-effective piping systems is driving the growth of the fiberglass pipes market. The use of fiberglass pipes in the petrochemical industry has resulted in improved safety, reduced maintenance costs, and increased service life compared to traditional metallic piping systems.