A Comprehensive Guide to Filament Wound Epoxy Tubes

Introduction

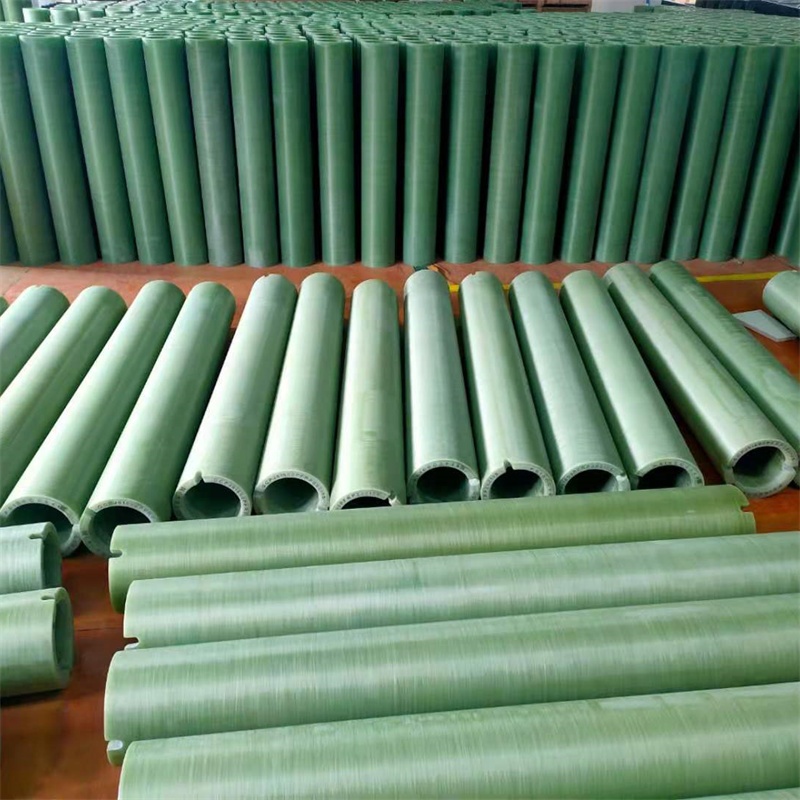

Filament wound epoxy tubes are lightweight, high-strength tubes made from a combination of epoxy resin and reinforcing fibers. They serve a variety of industrial applications, ranging from aerospace to sports equipment. The manufacturing process of these tubes involves winding reinforcing fibers around a rotating mandrel and then curing them in an oven. Filament winding technology has been around since the 1950s, but recent innovations have improved their properties and lowered manufacturing costs.

Manufacturing process of filament wound epoxy tubes

The manufacturing process of filament wound epoxy tubes involves several steps:

A. Material selection: The first step is to select the appropriate reinforcing fibers and epoxy resin for the desired properties of the final product. Fibers such as carbon, glass, or aramid are typically used to provide strength, whereas epoxy resin is used as a binding material.

B. Machine setup: The next step is to set up the machine for filament winding. This typically involves setting up a rotating mandrel and a fiber delivery system to guide the fibers onto the mandrel.

C. Filament winding process: The fibers are actively wound around the mandrel in a specific pattern, and the amount of resin applied is carefully controlled to ensure even distribution. The winding pattern can be controlled to vary the strength and flexibility of the tubes.

D. Curing process: After winding, the tubes are cured at high temperatures in an oven. The curing process can take several hours, depending on the size and complexity of the tubes. During this time, the epoxy resin hardens and forms a strong bond with the reinforcing fibers.

E. Machining and finishing: Once cured, the tubes are machined or finished to create a smooth surface and the desired dimensions.

Properties of filament wound epoxy tubes

Filament wound epoxy tubes offer several desirable characteristics, including:

A. Rigidity and strength: The reinforcing fibers, coupled with the epoxy resin, create a rigid and high-strength material that can withstand high loads and stresses.

B. Chemical resistance: Epoxy resin is known for its excellent resistance to chemicals and solvents, making filament wound epoxy tubes well-suited for use in harsh environments.

C. Temperature resistance: The curing process increases the heat resistance of the tubes, making them suitable for use in high-temperature applications.

D. Electrical insulation: The insulating properties of epoxy resin make filament wound epoxy tubes an excellent choice for electrical insulation and shielding.

Applications of filament wound epoxy tubes

Filament wound epoxy tubes find extensive use in various industries, including:

Aerospace industry: Filament wound epoxy tubes are used to make components such as shafts, beams, and struts for aircraft and spacecraft.

Automotive industry: These tubes are used in high-performance vehicles for the suspension, drive shafts, and other critical parts.

Marine industry: Filament wound epoxy tubes are used for boat hulls, masts, and spars.

Sports equipment: Filament wound epoxy tubes are used in sports equipment such as golf club shafts and fishing rods.

Industrial equipment: These tubes are used in oil and gas industry machinery, as well as in the fabrication of pipes and tanks.

Advantages of filament wound epoxy tubes

Filament wound epoxy tubes offer several advantages, including:

A. Reduced weight and cost: The use of lightweight reinforcing fibers and the high strength of the epoxy resin reduces the weight and cost of these tubes compared to traditional metal tubing.

B. Increased strength and durability: The epoxy resin and reinforcing fibers create a high-strength material that can withstand high loads and stresses, making filament wound epoxy tubes more durable than traditional tubing.

C. Customizable design options: Filament winding technology allows for a wide range of design options, such as adjusting the winding pattern for specific applications.

D. Easy to maintain and install: These tubes are relatively easy to maintain and install due to their lightweight and simple design.

Challenges and limitations of filament wound epoxy tubes

There are several challenges and limitations associated with the manufacturing and use of filament wound epoxy tubes, including:

A. High manufacturing cost: The high cost of materials and equipment required for filament winding can make these tubes more expensive than traditional tubing.

B. Limited manufacturing capabilities for large diameters: The current manufacturing process limits the diameter of the tubes that can be produced, making them less suitable for some applications.

C. Limited aesthetic options: Filament wound epoxy tubes have a uniform color and finish, limiting their aesthetic options compared to traditional tubing.

D. High technical skills required for production: The manufacturing process of these tubes requires a high level of technical skill and expertise, making it difficult for smaller manufacturers to enter the market.

Future developments and trends in the filament wound epoxy tube industry

The filament wound epoxy tube industry is poised for continued growth and innovation, with several developments and trends on the horizon, including:

A. Continuous improvement in material selection: Research and development will continue to lead to improved materials that offer increased strength, reduced weight, and other desirable characteristics.

B. Increased automation in production processes: Advances in automation technology will likely lead to greater efficiency and decreased manufacturing costs.

C. Integration of digital technology in filament winding processes: The use of 3D printing and other digital technologies may revolutionize the manufacturing process.

D. Development of sustainable and eco-friendly alternatives: As environmental concerns continue to grow, there will likely be a push towards more sustainable and eco-friendly manufacturing processes and materials.

Conclusion

Filament wound epoxy tubes offer a lightweight, high-strength solution for a variety of applications. While the manufacturing process can be complex and expensive, recent advancements in technology have led to improved properties and lower costs. As the industry continues to grow, further innovation and development will likely drive improvements in material selection, manufacturing processes, and sustainability practices.

What are filament wound epoxy tubes, and what industries do they apply to? Filament wound epoxy tubes are a type of composite material made from resin and glass, carbon, or other fibers. The tubes are fabricated through a filament winding process and are used in various industries such as aerospace, automotive, sports equipment, marine, and industrial equipment.

FAQ

What is the process of manufacturing filament wound epoxy tubes?

The manufacturing process involves material selection, machine setup, filament winding, curing, and machining/finishing. The fibers are wound around a mandrel in a specific pattern and direction to achieve the desired mechanical properties of the finished product.

What properties do filament wound epoxy tubes have, and what are their applications?

Filament wound epoxy tubes have excellent rigidity and strength, chemical and temperature resistance, and electrical insulation properties. They are used in various applications such as aerospace structures and components, automotive drive shafts, marine and offshore structures, sports equipment, and industrial equipment.

What are the advantages and disadvantages of filament wound epoxy tubes?

The advantages include reduced weight and cost, increased strength and durability, customizable design options, and easy maintenance and installation. The drawbacks are high manufacturing costs, limited manufacturing capabilities for large diameters, limited aesthetic options, and high technical skills required for production.

What are the future developments and trends in the filament wound epoxy tube industry?

The industry is continually improving material selection, increasing automation in production processes, integrating digital technology in filament winding processes, and developing sustainable and eco-friendly alternatives. These advancements will lead to more efficient manufacturing processes, increased production capacity, greater design flexibility, and wider applications of filament wound epoxy tubes.